GILBERT, Ariz. - An Arizona company says they've developed a better, cheaper way to make biofuels, and more of it, from algae. Diversified Energy Corporation has developed a "breakthrough algae production system". The system is called "Simgae", for 'simple algae'. It utilizes common agriculture and irrigation components to produce algae at a fraction of the cost of competing systems. At 1/2 - 1/16th the capital cost, profitable oil production costs at $0.08 - $0.12/pound, and low operations and maintenance requirements, the system offer the biofuels industry access to cheap and readily available oils and starches for the production of biodiesel, ethanol, and other renewable fuels.

GILBERT, Ariz. - An Arizona company says they've developed a better, cheaper way to make biofuels, and more of it, from algae.

Diversified Energy Corporation has developed a "breakthrough algae production system". The system is called "Simgae", for simple algae. It utilizes common agriculture and irrigation components to produce algae at a fraction of the cost of competing systems. At 1/2 - 1/16th the capital cost, profitable oil production costs at $0.08 - $0.12/pound, and low operations and maintenance requirements, the system offer the biofuels industry access to cheap and readily available oils and starches for the production of biodiesel, ethanol, and other renewable fuels.

Algae has received substantial attention as a high-promise source of biofuel oils to alleviate the supply shortages and high prices of traditional feedstock sources. Since the feedstock inputs can contribute 60 - 80% of the production cost of biofuel, keeping the feedstock cheap and readily available is critical to the renewable fuels industry. Algae has been shown to produce 30X more oil and require 1/100th the water per acre when compared to traditional crops. In addition, the carbohydrate and protein components of algae can be used for a multitude of other purposes including ethanol production, feed, fertilizer, etc. Algae requires very little care to grow, only needing sunlight, water, carbon dioxide (CO2), and basic nutrients. Its ability to ingest carbon dioxide and produce oxygen is particularly attractive to curtail carbon emissions.

Given all these benefits widespread algae production has yet to materialize. The reason for the lack of market adoption is centered upon the significant capital and operations and maintenance costs to build and maintain the algae systems. These costs have been the Achilles' heel for investors and developers. Typical architectures rely on a series of rigid and complex frameworks and structures. As a consequence, capital costs can be anywhere from $100k's to over $1M/acre. When factoring in the thousands of algae acres required for any meaningful volume of oils, these up-front costs can kill a project.

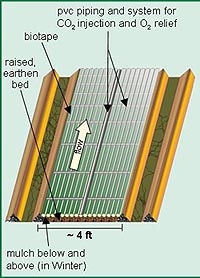

Simgae offers a complete paradigm shift by delivering an agriculture-based solution to large scale algae production. Instead of creating elaborate architectures designed to push yield to its utmost maximum, the proposed system makes cost and simplicity the driving variables. The approach can be thought of as the "farmer's solution" to algae production. The system uses unique thin walled polyethylene tubing, called Algae Biotape(R), similar to conventional drip irrigation tubes. The patent pending bio-tape is laid out in parallel across a field. Under pressure, water containing the necessary nutrients and a small fraction of algae are slowly introduced into the biotape. Carbon dioxide is injected periodically and after roughly 24 hours the flow leaves the Algae Biotape(R) with a markedly greater concentration of algae than was started. All the supporting hardware components and processes involved in Simgae are direct applications from the agriculture industry. Re-use of these practices avoids the need for expensive and complex hardware and costly installation and maintenance.

!ADVERTISEMENT!

The Simgae design is expected to provide an annual algae yield of 100 - 200 dry tons per acre. Capital costs are expected to be approximately $45k - $60k (a 2 - 16 times improvement over competing systems) and profitable oil production costs are estimated at only $0.08 - $0.12/pound. These oil costs compare to recent market prices of feedstock oils anywhere from $0.25 - $0.44/pound.

Jeff Hassannia, Vice President of Business Development for Diversified Energy, commented, "The renewable fuels industry is in dire need of feedstock oils that are low priced and readily available. Algae is the perfect solution to this challenge, while at the same time helping to clean up the environment. Simgae will finally offer a simple, yet elegant means of bringing algae to the market at very reasonable costs." Ben Cloud, President and COO of XL Renewables, remarked, "We've kept the veil on Simgae(TM) until we were absolutely confident in its performance and economics. This is the right technology at the right time to deliver algae biomass for use as a feedstock for biofuel oils, super-antioxidant animal feeds, starches to the ethanol industry, and many other uses. All of this is packaged in a cost effective, easy to install and maintain system that also cleans dirty water and converts carbon dioxide to oxygen through photosynthesis. We are thrilled to be partnered with Diversified Energy to introduce Simgae(TM) on a global basis."

The team is currently conducting a demonstration of the technology in Casa Grande, Arizona. Continued testing and system optimization is expected to occur through 2008.