Pure formaldehyde is a gas and is commonly found as a s decomposition product from adhesives which are used to make a wide range of building materials and products. Exposure to formaldehyde can cause adverse public health effects including eye, nose and throat irritation, other respiratory symptoms and, in certain cases, cancer. When treated with phenol, urea, or melamine, formaldehyde produces, respectively, hard thermoset phenol formaldehyde resin, urea formaldehyde resin, and melamine resin. These polymers are common permanent adhesives used in plywood and carpeting. hence there is a potential for wide spread public exposure. The U.S. Environmental Protection Agency (EPA) has proposed two rules to help protect Americans from exposure to the harmful chemical formaldehyde, consistent with a Federal law unanimously passed by Congress in 2010. These rules ensure that composite wood products produced domestically or imported into the United States meet the formaldehyde emission standards established by Congress.

Pure formaldehyde is a gas and is commonly found as a s decomposition product from adhesives which are used to make a wide range of building materials and products. Exposure to formaldehyde can cause adverse public health effects including eye, nose and throat irritation, other respiratory symptoms and, in certain cases, cancer. When treated with phenol, urea, or melamine, formaldehyde produces, respectively, hard thermoset phenol formaldehyde resin, urea formaldehyde resin, and melamine resin. These polymers are common permanent adhesives used in plywood and carpeting. hence there is a potential for wide spread public exposure. The U.S. Environmental Protection Agency (EPA) has proposed two rules to help protect Americans from exposure to the harmful chemical formaldehyde, consistent with a Federal law unanimously passed by Congress in 2010. These rules ensure that composite wood products produced domestically or imported into the United States meet the formaldehyde emission standards established by Congress.

!ADVERTISEMENT!

"The proposed regulations announced today reflect EPA’s continued efforts to protect the public from exposure to harmful chemicals in their daily lives," said James J. Jones, EPA’s acting assistant administrator for the Office of Chemical Safety and Pollution Prevention. “Once final, the rules will reduce the public’s exposure to this harmful chemical found in many products in our homes and workplace.

EPA's first proposal limits how much formaldehyde may be emitted from hardwood plywood, medium-density fiberboard, particleboard and finished goods, that are sold, supplied, offered for sale, manufactured, or imported in the United States. The emitted formaldehyde may be left over from the resin or composite wood making process or be released when the resin degrades in the presence of heat and humidity.

This proposal also includes testing requirements, laminated product provisions, product labeling requirements, chain of custody documentation, recordkeeping, a stockpiling prohibition, and enforcement provisions. It also includes a common-sense exemption from some testing and record-keeping requirements for products made with no-added formaldehyde resins.

The second proposal establishes a third-party certification framework designed to ensure that manufacturers of composite wood products meet the TSCA formaldehyde emission standards by having their composite wood products certified though an accredited third-party certifier. It would also establish eligibility requirements and responsibilities for third-party certifier's and the EPA-recognized accreditation bodies who would accredit them. This robust proposed third-party certification program will level the playing field by ensuring composite wood products sold in this country meet the emission standards in the rule regardless of whether they were made in the United States or not.

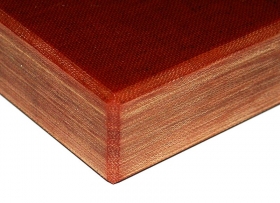

The high cross linking characteristic gives phenolic resin (with formaldehyde) its hardness, good thermal stability, and chemical imperviousness.

These resins are major polymeric resin materials widely used for gluing and bonding building materials. Exterior plywood, oriented strand boards , and engineered laminated composite lumber are typical applications.

Approximately 1 million metric tons of urea-formaldehyde are produced every year. Over 70% of this production is then put into use by the forest industry products. produces a great resin for bonding particleboard (61%), medium density fiberboard (27%), hardwood plywood (5%), and laminating adhesives.

The product is widely chosen as an adhesive resin due to its high reactivity, good performance, and low price. Urea-formaldehyde resin is a chemical combination of urea and formaldehyde.

For further information see Formaldehyde and EPA rules.

Formaldehyde Product image via Wikipedia.