Lignocellulosic biomass—plant matter such as cornstalks, straw, and woody plants—is a sustainable source for production of bio-based fuels and chemicals. However, the deconstruction of biomass is one of the most complex processes in bioenergy technologies. Although researchers at the US Department of Energy’s (DOE’s) Oak Ridge National Laboratory (ORNL) had already uncovered information about how woody plants and waste biomass can be converted into biofuel more easily, they have now discovered the chemical details behind that process.

Lignocellulosic biomass—plant matter such as cornstalks, straw, and woody plants—is a sustainable source for production of bio-based fuels and chemicals. However, the deconstruction of biomass is one of the most complex processes in bioenergy technologies. Although researchers at the US Department of Energy’s (DOE’s) Oak Ridge National Laboratory (ORNL) had already uncovered information about how woody plants and waste biomass can be converted into biofuel more easily, they have now discovered the chemical details behind that process.

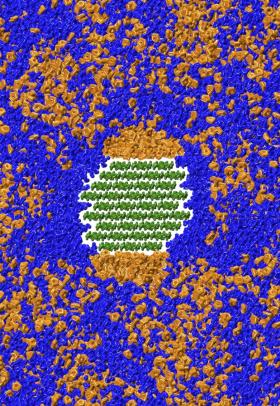

A team led by Jeremy Smith, a University of Tennessee (UT)–ORNL Governor’s Chair and the director of the UT–ORNL Center for Molecular Biophysics (CMB), uses computer simulations to investigate the chemistry of biomass deconstruction. Smith’s collaborators from the BioEnergy Science Center, a DOE Bioenergy Research Center led by ORNL, previously developed a pretreatment method for breaking down biomass that initiates delignification, the removal of the rigid plant molecule lignin. The cosolvent enhanced lignocellulose fractionation pretreatment involves aqueous solutions of tetrahydrofuran (THF), a versatile organic solvent. This cosolvent mixture uniquely interacts with cellulose, the main structural component of plant cell walls, to enable its breakdown.

Continue reading at Oak Ridge National Laboratory

Image: An illustration that demonstrates how THF (orange) and water (blue) phase separate on the surface of cellulose (green), thus facilitating its breakdown

Credits: Barmak Mostofian