Lakes Environmental Research announced today the issuance of patent number 9,605,212 B2 by the US Patent Office that covers a revolutionary oil sands recovery process. The “Novel Ultra-Low Water Oil-Sands Recovery Process” (NUWORP) significantly reduces, with the potential to eliminate, three of the greatest barriers to wider adoption of oil sands production.

Lakes Environmental Research announced today the issuance of patent number 9,605,212 B2 by the US Patent Office that covers a revolutionary oil sands recovery process. The “Novel Ultra-Low Water Oil-Sands Recovery Process” (NUWORP) significantly reduces, with the potential to eliminate, three of the greatest barriers to wider adoption of oil sands production. NUWORP is designed to

- Avoid entirely the emission of greenhouse gases (GHG),

- Eliminate the need for waste ponds, and

- Eliminate the need for diluted bitumen (dilbit) pipelines by directly outputting value added products such as gasoline.

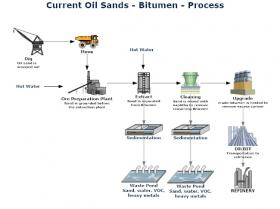

Presently, the vast oil sands reserves in Western Canada have their market restricted by global warming and climate change concerns associated with the current high carbon dioxide (CO2) intensity of oil sands oil extraction. Extraction is also restricted by environmental impact concerns from waste ponds leaking toxics into local waterways or killing birds that landing on them. Furthermore, there are resistance to new pipelines carrying diluted bitumen, which leave behind a hard to clean molasses like residue, once the diluent evaporates after a leakage.

Prof. Roydon Fraser, from the University of Waterloo and NUWORP’s coauthor explains that “a dry oil sands process is mandatory to gurantee the elimination of the large tail waste ponds that exist in current practice.” Prof. Jesse Thé, further explains that “These tail ponds have a large visual impact, and contain minor amounts of residual hydrocarbons. The current approach eliminates the need for water and places the extraction process very close to the mines. This way, cleaner sand can be trucked back to the mines.”

Read more at Lakes Environmental Software

Image: Current oil sands - Bitumen - Process (Credit: Jesse The' and Roydon Fraser)