Nanoengineers at the University of California San Diego have developed the first printed battery that is flexible, stretchable and rechargeable. The zinc batteries could be used to power everything from wearable sensors to solar cells and other kinds of electronics. The work appears in the April 19, 2017 issue of Advanced Energy Materials.

The researchers made the printed batteries flexible and stretchable by incorporating a hyper-elastic polymer material made from isoprene, one of the main ingredients in rubber, and polystyrene, a resin-like component. The substance, known as SIS, allows the batteries to stretch to twice their size, in any direction, without suffering damage.

>> Read the Full Article

A new type of nanocatalyst can result in the long-awaited commercial breakthrough for fuel cell cars. Research results from Chalmers University of Technology and Technical University of Denmark show that it is possible to significantly reduce the need for platinum, a precious and rare metal, by creating a nanoalloy using a new production technique. The technology is also well suited for mass production.

“A nano solution is needed to mass-produce resource-efficient catalysts for fuel cells. With our method, only one tenth as much platinum is needed for the most demanding reactions. This can reduce the amount of platinum required for a fuel cell by about 70 per cent”, says Björn Wickman, researcher at the Department of Physics at Chalmers.

>> Read the Full Article

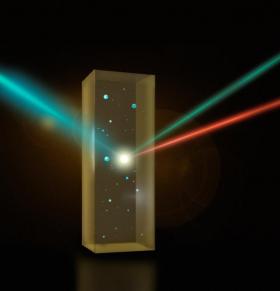

How can we burn natural gas without releasing CO2 into the air? This feat is achieved using a special combustion method that TU Wien has been researching for years: chemical looping combustion (CLC). In this process, CO2 can be isolated during combustion without having to use any additional energy, which means it can then go on to be stored. This prevents it from being released into the atmosphere.

The method had already been applied successfully in a test facility with 100 kW fuel power. An international research project has now managed to increase the scale of the technology significantly, thus creating all the necessary conditions to enable a fully functional demonstration facility to be built in the 10 MW range.

>> Read the Full Article

By introducing defects into the perfect surface of graphene on silicon carbide, researchers at LiU have increased the capacity of the material to store electrical charge. This result, which has been published in the scientific journal Electrochimica Acta, increases our knowledge of how this ultrathin material can be used.

The thinnest material ever produced, graphene, consists of a single layer of carbon atoms. They form a chicken-wire structure one atom thick, with unique properties. It is around 200 times stronger than steel, and highly flexible. It is transparent, but gases and liquids cannot pass through it. In addition, it is an excellent conductor of electricity. There are many ideas about how this nanomaterial can be used, and research into future applications is intense.

>> Read the Full Article

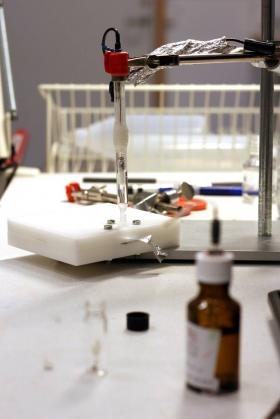

Nanometric-sized water drops are everywhere - in the air as droplets or aerosols, in our bodies as medication, and in the earth, within rocks and oil fields. To understand the behavior of these drops, it is necessary to know how they interact with their hydrophobic environment. This interaction takes places at the curved droplet interface, a sub-nanometric region that surrounds the small pocket of water. Researchers from EPFL, in collaboration with the institute AMOLF in the Netherlands, were able to observe what was going on in this particular region. They discovered that molecules on the surface of the drops were much more ordered than expected. Their surprising results have been published in Nature Communications. They pave the way to a better understanding of atmospheric, biological and geological processes.

>> Read the Full Article

ENN

Environmental News Network -- Know Your Environment

ENN

Environmental News Network -- Know Your Environment