Washington State University researchers have created a sustainable alternative to traditional concrete using coal fly ash, a waste product of coal-based electricity generation.

The advance tackles two major environmental problems at once by making use of coal production waste and by significantly reducing the environmental impact of concrete production.

Xianming Shi, associate professor in WSU’s Department of Civil and Environmental Engineering, and graduate student Gang Xu, have developed a strong, durable concrete that uses fly ash as a binder and eliminates the use of environmentally intensive cement. They report on their work in the August issue of the journal, Fuel.

Washington State University researchers have created a sustainable alternative to traditional concrete using coal fly ash, a waste product of coal-based electricity generation.

The advance tackles two major environmental problems at once by making use of coal production waste and by significantly reducing the environmental impact of concrete production.

Xianming Shi, associate professor in WSU’s Department of Civil and Environmental Engineering, and graduate student Gang Xu, have developed a strong, durable concrete that uses fly ash as a binder and eliminates the use of environmentally intensive cement. They report on their work in the August issue of the journal, Fuel.

Reduces energy demand, greenhouse emissions

Production of traditional concrete, which is made by combining cement with sand and gravel, contributes between five and eight percent of greenhouse gas emissions worldwide. That’s because cement, the key ingredient in concrete, requires high temperatures and a tremendous amount of energy to produce.

Read more at Washington State University

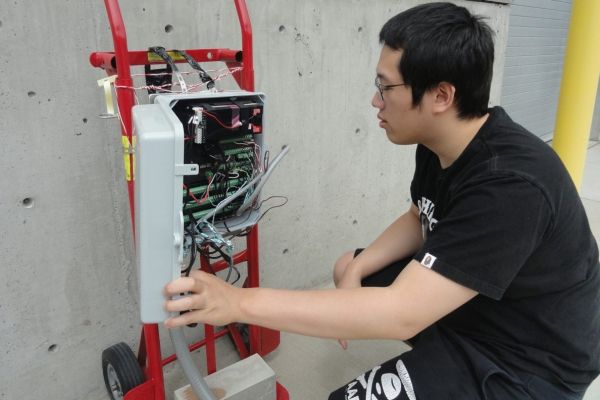

Image: Chemical engineering student Ka Fung Wong looks at the data log that's gathering information from sensors buried under the concrete test plot. CREDIT: Washington State University