Water is always precious. Increased natural gas production is happening ion the US. But natural gas wells have problems: Large volumes of deep water, often heavily laden with salts and minerals, flow out along with the gas. That so-called produced water must be disposed of, or cleaned. Once cleaned it has beneficial reuse in often arid regions.

Water is always precious. Increased natural gas production is happening ion the US. But natural gas wells have problems: Large volumes of deep water, often heavily laden with salts and minerals, flow out along with the gas. That so-called produced water must be disposed of, or cleaned. Once cleaned it has beneficial reuse in often arid regions.

!ADVERTISEMENT!

A process developed by engineers at MIT could solve the problem and produce clean water at relatively low cost. After further development, the process could also lead to inexpensive, efficient desalination plants for communities in the developing world, the researchers say.

The new technology is described in a series of papers recently published in three journals: the International Journal of Heat and Mass Transfer, Applied Energy and the American Institute of Chemical Engineers’ AIChE Journal. The research is the work of a team including MIT postdoc Prakash Narayan, mechanical engineering professor John H. Lienhard V, and collaborators at King Fahd University of Petroleum and Minerals (KFUPM) in Saudi Arabia.

The method is a variation of the standard distillation process, in which salty water is vaporized and then condenses on a cold surface; the salt separates out during evaporation. But this process is energy-intensive — and therefore costly — because all the water must be heated to the boiling point, while the condensing surfaces must be kept cold.

In the new process, water well below the boiling point is vaporized by direct contact with a carrier gas; the moist air is subsequently bubbled through cooler water where the purified vapor condenses. But the temperature difference between the warm and cool water is much less than in conventional dehumidifiers, and the surface area provided by the small bubbles is much greater than that of a flat condenser surface, leading to a more efficient process.

The traditional version of this process is called a humidification dehumidification (HDH) desalination system. While other groups have designed HDH systems, this new version requires far less energy than previous systems, the team says.

The solar humidification-dehumidification method is a thermal water desalination method. It is based on evaporation of sea water or brackish water and consecutive condensation of the generated humid air, mostly at ambient pressure. This process mimics the natural water cycle, but over a much shorter time frame.

The simplest configuration is implemented in the solar still, evaporating the sea water inside a glass covered box and condensing the water vapor on the lower side of the glass cover. More sophisticated designs separate the solar heat gain section from the evaporation-condensation chamber. An optimized design comprises separated evaporation and condensation sections. A significant part of the heat consumed for evaporation can be regained during condensation. An example for such an optimized thermal desalination cycle is the multiple-effect humidification method of transportation.

Lienhard says, "We became interested in the HDH process at the start of our collaboration with KFUPM as a means of providing water to off-grid regions of the developing world. Both the MIT and the KFUPM faculty wanted to develop a technology that might benefit people all over the world."

At the beginning of his doctoral thesis research, Narayan was focused, he says, on ways "to increase energy efficiency and thermal efficiency, and to reduce size and cost" for desalination plants.

Lienhard notes that the HDH technology had not previously been the target of systematic analysis: "Over a period of years, our group developed new thermodynamic methods for assessment of these cycles, followed by a deep understanding of the causes of energy inefficiency in them. Eventually, this led us to the new configurations and components that are described in these latest publications."

The researchers have already filed for patents on the system, and the team has set up a company to commercialize the process in collaboration with another MIT group that has been pursuing a related system for desalination. While Narayan says the team’s ultimate goal is desalination in developing countries, it turns out that the system is especially well suited for treating the produced water that comes from natural gas wells.

The water and other fluids used to open wells through hydraulic fracturing — also known as fracking — are a somewhat different matter, requiring other kinds of treatment and disposal. But a much bigger issue for the operators of these wells is the ongoing treatment of produced water, which represents a significant expense. This water is typically several times saltier than seawater, which makes it a particularly good candidate for treatment with the HDH process, Narayan says: Unlike membrane-based desalination systems, this system’s efficiency is unaffected by saltier water.

Their next step is to scale up to a plant about two to three times the size of this initial unit, which calculations show should be an optimal size. Narayan says he expects the first commercial plants could be in operation within about two years.

For further information see Clean Water.

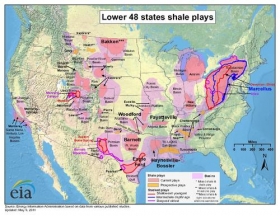

Shale Gas image via Wikipedia