To make natural gas and biogas suitable for use, the methane has to be separated from the CO?. This involves the use of membranes: filters that stop the methane and let the CO? pass through. Researchers at KU Leuven have developed a new membrane that makes the separation process much more effective.

To make natural gas and biogas suitable for use, the methane has to be separated from the CO?. This involves the use of membranes: filters that stop the methane and let the CO? pass through. Researchers at KU Leuven have developed a new membrane that makes the separation process much more effective.

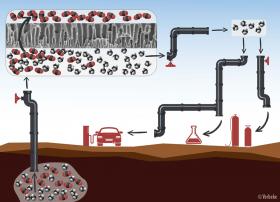

When it comes to extracting natural gas or producing biogas, it’s all about the methane. But methane is never found in its pure form. Natural gas, for instance, always contains quite a bit of carbon dioxide (the greenhouse gas CO2), sometimes up to 50 percent. To purify the methane – or, in other words, remove the CO2 – the industry often uses membranes. These membranes function as molecular sieves that separate the methane and the CO2. The methane can then be used as a source of energy for heating, for the production of chemicals, or as fuel, while the CO2 can be reused as a building block for renewable fuels and chemicals.

Read more at KU Leuven

Image: Natural gas or biogas always needs to be purified before use. First, the methane molecules (in black and white) are separated from the CO2 molecules (in red and black) by means of membranes with tiny pores through which only the CO2 can pass. After the purification process, the methane can be used as fuel, for heating, or for the production of chemicals.

Image Credit: Verbeke / KU Leuven